Transforming to add value

Transforming projects into solutions

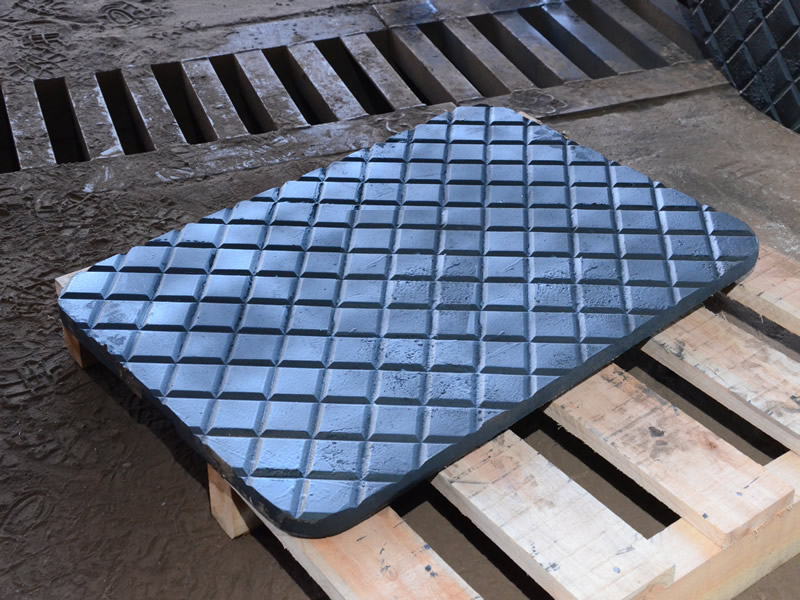

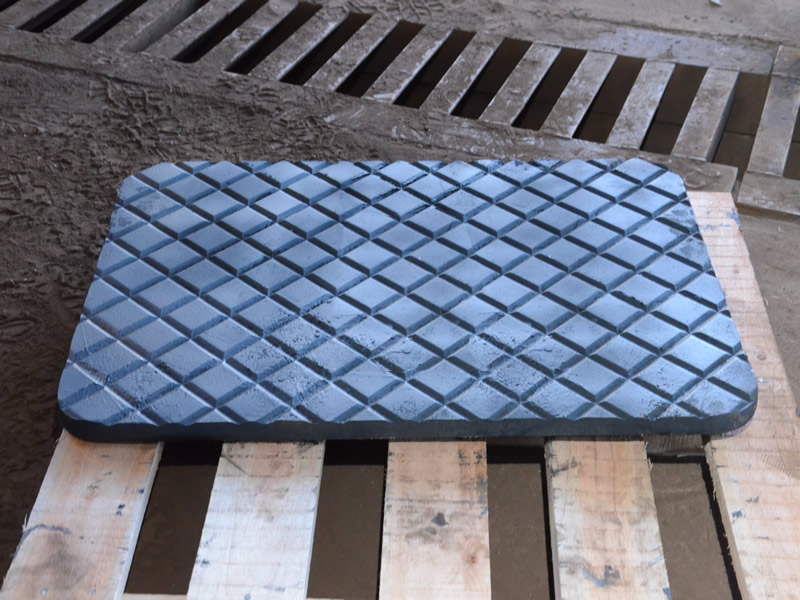

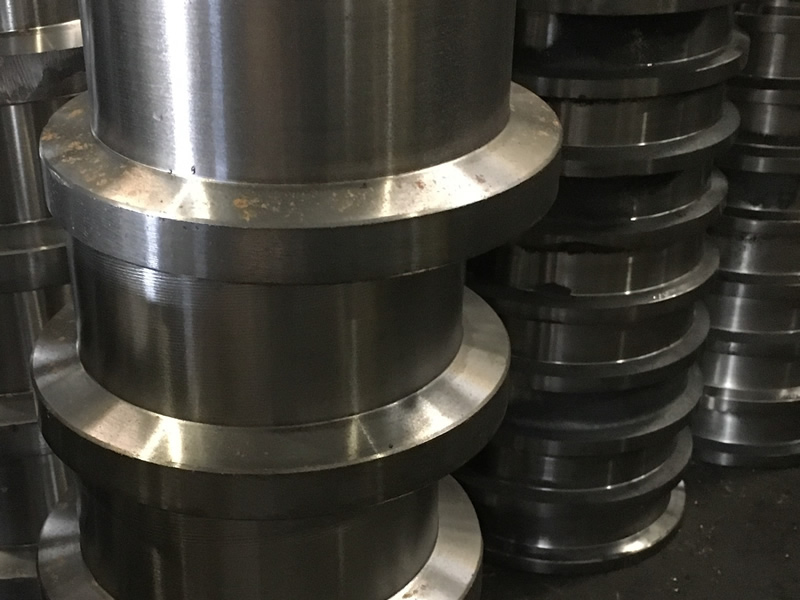

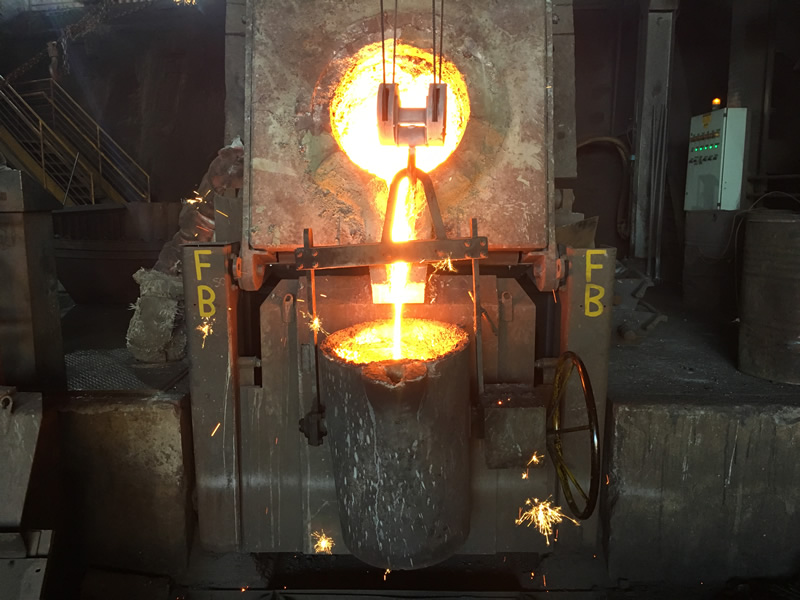

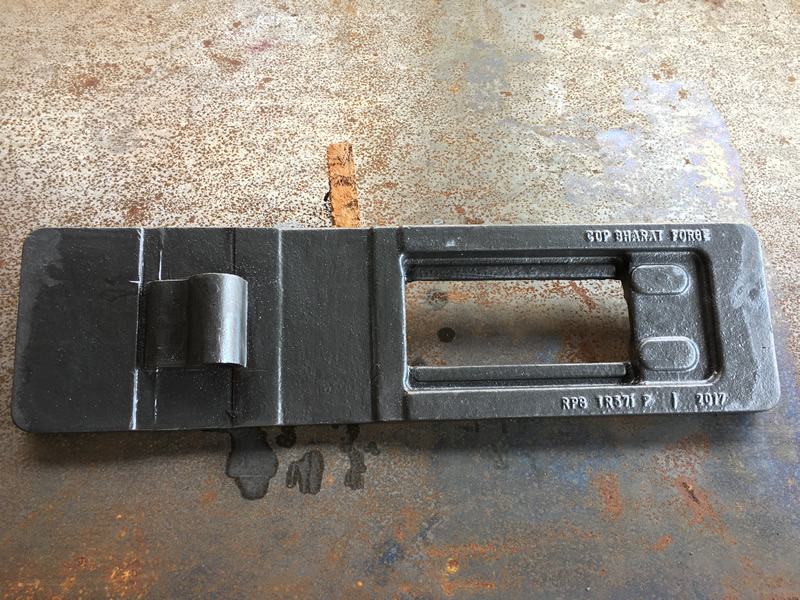

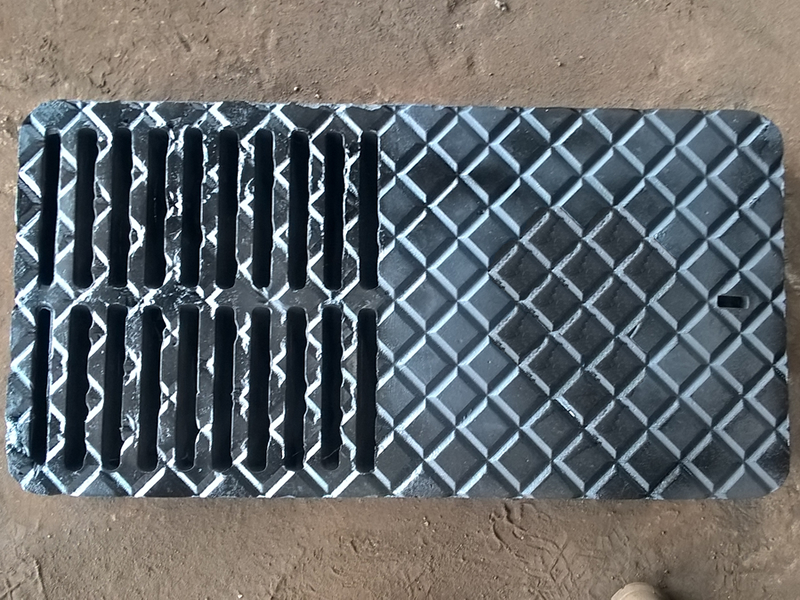

With a production capacity of 250 tons/month of castings, Fundição Alterosa uses grey, nodular, and white iron alloys as raw materials. The foundry includes the following facilities: one 600-kW Inductotherm furnace with two 2-ton crucibles; one Cold Box machine with a capacity of 6 tons/hour of sand; one Pep-set pivoting machine with a capacity of 6 tons/hour of sand; one shot blasting system with blasting capacity of 6 tons/hour; and high-frequency finishing (trimming) devices for high quality castings finish and outstanding productivity.

In order to ensure excellent metallurgical quality of our castings, our foundry relies on optical spectrometer for chemical analysis. The outcome is full assertiveness in chemical composition ranges in our products. Moreover, we conduct metallographic and mechanical tests; the latter are carried out by an INMETRO-certified laboratory.

News

U.S. Dollar exchange rate

| Buying | Selling | |

|---|---|---|

| Commercial exchange rate (in R$) | 5.2465 | 5.2476 |

| Tourism exchange rate (in R$) | 5.2581 | 5.4381 |

| Source: | UOL Economia | |

Useful Links

Read the news about the pig iron industry in Brazil and across the world.

Our location

Rua Pequi, 189 - Santos Dumont

Pará de Minas | MG | Brazil

CEP: 35660-308

Telephone: +55 (37) 3232-0800

WhatsApp: +55 (37) 99820-9444